EtherNet/IP

Introduction

This section explains how to use the CM1-T Cool Muscle motor with EtherNet/IP. It is assumed there is a basic knowledge of EtherNet/IP and PLC programming. The implementation makes use of the different Direct Control in the motor. It does not use CML logic and bank programming. However, setup (K) and controller gain (H) parameters are used for things like motor resolution, s-curve, software limits, etc. These are all accessible to be setup with Control Room or over explicit messages.

Device Profile

The CM1-T uses a generic device profile. This is to allow it to be flexible and operate in a number of operation modes.

Direct Control Operation

This mode enables the PLC to directly control the motor. See Direct Control on how to use the I/O messages to control the motor. Add on instructions are supplied in the downloads section.

CML Operation

This mode lets to motor control itself through CML programming. The PLC reads and writes to registers to monitor and make changes how the motor operates.

I/O Messages

There are two distinct I/O Assemblies based on the operation mode required.

Direct Control Operation

I/O | Assembly Instance | Size |

|---|---|---|

Input | 100 | 36 |

Output | 112 | 28 |

Configuration | 1 | 0 |

T2O (Input) Message

Instance = 100

Size = 36 bytes

Byte | Name | Data Type |

|---|---|---|

0-3 | us50Counter | DINT |

4-7 | ActualPosition | DINT |

8-11 | MotionTarget | DINT |

12-15 | ActualSpeed | DINT |

16-17 | MotorStatus | INT |

18-19 | PercentActualCurrent | INT |

20-21 | PercentOverloadTorque | INT |

22-23 | AnalogIN | INT |

24-25 | DCVoltage | INT |

26 | DigitalIO | SINT |

27 | Temperature | SINT |

28 | ModeOfOperationDisplay | SINT |

29 | ErrorCode(1) | SINT |

30-31 | ReadAddress1 | INT |

32-35 | ReadValue1 | DINT |

(1) - ErrorCode is currently reserved and returns 0. Use MotorStatus to get motor error information

O2T (Output) Message

Instance = 112

Size = 28

Byte | Name | Data Type |

|---|---|---|

0-3 | TargetPosition | DINT |

4-7 | TargetSpeed | DINT |

8-9 | TargetTorque | INT |

10-11 | TargetAccelertion | INT |

12-13 | TargetDeceleration | INT |

14-15 | Controlword | INT |

16 | ModeOfOperation | SINT |

17 | DigitalOUT | SINT |

18-19 | WriteAddress1 | INT |

20-23 | WriteValue1 | DINT |

24-25 | ReadAddress1 | INT |

26-27 | PAD | INT |

CML Operation

I/O | Assembly Instance | Size |

|---|---|---|

Input | 101 | 60 |

Output | 113 | 44 |

Configuration | 1 | 0 |

T2O (Input) Message

Instance = 101

Size = 60 bytes

Byte | Name | Data Type |

|---|---|---|

0-3 | us50Counter | DINT |

4-7 | ActualPosition | DINT |

8-11 | MotionTarget | DINT |

12-15 | ActualSpeed | DINT |

16-17 | MotorStatus | INT |

18-19 | PercentActualCurrent | INT |

20-21 | PercentOverloadTorque | INT |

22-23 | AnalogIN | INT |

24-25 | DCVoltage | INT |

26 | DigitalIO | SINT |

27 | Temperature | SINT |

28 | ModeOfOperationDisplay | SINT |

29 | ErrorCode(1) | SINT |

30-31 | ReadAddress1 | INT |

32-35 | ReadValue1 | DINT |

36-37 | ReadAddress2 | INT |

38-39 | ReadAddress3 | INT |

40-41 | ReadAddress4 | INT |

42-43 | ReadAddress5 | INT |

44-47 | ReadValue2 | DINT |

48-51 | RadValue3 | DINT |

52-55 | ReadValue4 | DINT |

56-59 | ReadValue5 | DINT |

(1) - ErrorCode is currently reserved and returns 0. Use MotorStatus to get motor error information

O2T (Output) Message

Instance = 113

Size = 44

Byte | Name | Data Type |

|---|---|---|

0-3 | WriteValue1 | DINT |

4-7 | WriteValue2 | DINT |

8-11 | WriteValue3 | DINT |

12-15 | WriteValue4 | DINT |

16-19 | WriteValue5 | DINT |

20-21 | WriteAddress1 | INT |

22-23 | WriteAddress2 | INT |

24-25 | WriteAddress3 | INT |

26-27 | WriteAddress4 | INT |

28-29 | WriteAddress5 | INT |

30-31 | ReadAddress1 | INT |

32-33 | ReadAddress2 | INT |

34-35 | ReadAddress3 | INT |

36-37 | ReadAddress4 | INT |

38-39 | ReadAddress5 | INT |

40 | DigitalOUT | SINT |

41 | PAD | SINT |

42-43 | PAD | INT |

Read/Write Motor Registers

In the I/O messages there is the ability to read and write to internal motor registers. These registers could be configured as flags, input counters, or other custom operations.

Direct Operation has

1 x read register

1 x write register

CML Operation has

5 x read registers

5 x write registers

The register addresses can be changed after a cycle to read/write to more than 1 register.

Register Address

The register address is coded into a 2 byte (UINT16) format as follows

B1 | B0 |

|---|---|

Register Type (P, S, A, V, etc) | Register Number (0 to max) |

Register Address = Register Type Register Number

The following list maps the register type and the applicable number range

B1 Value (hex) | Register | Register No. Range | Example | ||

|---|---|---|---|---|---|

Register | Address | ||||

Hex | Decimal | ||||

16#00 | N/A | N/A | - | - | - |

16#01 | reserved | reserved | - | - | - |

16#02 | reserved | reserved | - | - | - |

16#03 | P | 0-25 | P0 | 16#0300 | 768 |

16#04 | S | 0-15 | S1 | 16#0x0401 | 1025 |

16#05 | A | 0-8 | A5 | 16#0x0505 | 1285 |

16#06 | T | 0-8 | T2 | 16#0x0602 | 1538 |

16#07 | M | 0-8 | M0 | 16#0x0700 | 1792 |

16#08 | R | 0-25 | R16 | 16#0x0810 | 2064 |

16#09 | N | 0-25 | N15 | 16#0x090F | 2319 |

16#0A | V | 0-15 | V10 | 16#0x0A0A | 2570 |

For a complete list go to EtherNet/IP#Complete Register Address Map

Explicit Messages

K Parameters - Setup Parameters

Get Attribute Single - Service Code 0x0E

Set Attribute Single - Service Code 0x10

Class | 0x64 |

|---|---|

Instance | 1 |

Attribute | The attribute represents the K number. example: K37 → 37d → 0x25 |

H Parameters - Gain Parameters

Get Attribute Single - Service Code 0x0E

Set Attribute Single - Service Code 0x10

Class | 0x65 |

|---|---|

Instance | 1 |

Attribute | H0 → 0x01 |

Direct Control Operation

Control Modes

This section focuses on controlling the motor with the provided Add on Instructions (AOIs). These will satisfy most applications, however, if required, the motor can be controlled by setting the CM1-T objects directly (see I/O Messages). Understanding the Direct Control will be important in this case.

There are currently 3 main control modes available while running the motor over EtherNet/IP.

Position - this mode sets the motor to run to a target position. The position could be absolute or relative

Speed - this mode allows the motors speed to be controlled for continuous motion

Torque - this mode allows the motors torque to be controlled.

The control modes are mapped to the ModeOfOperation value from the CM1T_ControlMode AOI:

Control Mode | CM1T_ControlMode AOI value | O2T ModeOfOperation Value |

|---|---|---|

Position | 0 | 3 |

Speed | 1 | 3 |

Torque | 2 | 11 |

In addition:

Homing is an additional mode that can be executed at any point. Homing should start from a known safe state to avoid unexpected changes in motion

All modes can be switched to during motion. It is recommended the state is switched during a known safe state.

Torque can be limited in all modes. Running in torque mode will disable errors such as position error which can still occur in other modes if the set torque is too low. The torque is set in 0.1% of rated torque. The range is [0,1100]. By default the torque is set to 1100 when using the AOIs supplied.

All modes use common objects such as position, speed, torque, acceleration and controlword. Switching parameters in another mode will change the value in the existing mode.

Setting the Start bit to 0 will NOT halt motion. The HALT bit must be used to interrupt motion.

Position Mode

Absolute position and relative position both use the position mode. The key difference in operation between the two is the usage of the start bit in the CM1T_Controlword. An absolute move will accept a new position immediately if the start bit is 1.

Start Bit Usage

BIT | Name | Value | Description |

|---|---|---|---|

B0 | Start/New Set Point | 0 |

|

0 → 1 |

| ||

1 | Execute any changes in any of the profile registers immediately. |

Motion Parameters

Position moves will accept the following motion parameters. These will be processed immediately if the start bit is high.

Name | Unit | Data Type | Access |

|---|---|---|---|

PositionTarget | counts | DINT | AOI(2) or Axis tag |

SpeedTarget | counts/s | DINT | AOI or Axis tag |

AccelerationTarget | 1000 counts/s2 | INT | AOI or Axis tag |

DecelerationTarget(1) | 1000 counts/s2 | INT | AOI or Axis tag |

TorqueTarget | 0.1% rated torque | INT | Axis Tag |

(1) If the deceleration is set to 0 the acceleration value will be used

(2) MoveAbsolute or MoveRelative AOI

Speed Mode

A speed move has no target position and will continue to run at the target speed. Setting a -ve speed value will reverse direction.

Start Bit Usage

BIT | Name | Value | Description |

|---|---|---|---|

B0 | Start/New Set Point | 0 |

|

0 → 1 |

| ||

1 | Execute any changes in any of the profile registers immediately. |

Motion Parameters

Speed moves will accept the following motion parameters. These will be processed immediately if the start bit is high.

Name | Unit | Data Type | Access |

|---|---|---|---|

SpeedTarget | counts/s | DINT | AOI(2) or Axis tag |

AccelerationTarget | 1000 counts/s2 | INT | AOI or Axis tag |

DecelerationTarget(1) | 1000 counts/s2 | INT | AOI or Axis tag |

TorqueTarget | 0.1% rated torque (1) | INT | Axis Tag |

(1) If the deceleration is set to 0 the acceleration value will be used

(2) MoveSpeed AOI

Torque Mode

A torque move only uses a target torque and maximum speed. Acceleration of the motor should be limited by adjusting the target torque or speed.

Setting a -ve torque value will reverse direction.

Start Bit Usage

BIT | Name | Value | Description |

|---|---|---|---|

B0 | Start/New Set Point | 0 |

|

0 → 1 |

| ||

1 | Execute any changes in any of the profile registers immediately. |

Motion Parameters

Torque moves will accept the following motion parameters. These will be processed immediately if the start bit is high.

Name | Unit | Data Type | Access |

|---|---|---|---|

SpeedTarget | counts/s | DINT | AOI(1) or Axis tag |

TorqueTarget | 0.1% rated torque Range: ± 1100 Where:

| INT | AOI or Axis Tag |

(1) MoveTorque AOI

General Resources

EDS File

The CM1-T EtherNet/IP eds file can be found on the Datasheets and Downloads page.

CM1-T Library

The CM1-T Library for use with Codesys, Schneider, Beckhoff, Wago and other IEC 61131-3 PLCs can be found on the Datasheets and Downloads page.

RSLogix Resources

See Datasheets and Downloads to download the UDTs, AOIs and sample program.

User Data Types

Direct Control Operation

CM1T_Axis

The CM1-T_Axis data type defines how the bytes are assigned withing the IO message.

Name | Data Type | Description |

|---|---|---|

Input | SINT[36] | Data coming from the CM1-T |

Output | SINT[28] | Data going to the CM1-T |

us50Counter | DINT | Motor 50us counter |

ModeOfOperation | SINT | Select control mode |

ModeOfOperationDisplay | SINT | Current control mode |

Controlword | CM1T_Controlword | Control operation |

DriveStatus | CM1T_DriveStatus | Drive status |

PositionTarget | DINT | Target position for position move |

SpeedTarget | DINT | Max speed for target move |

TorqueTarget | INT | Max torque for target move |

AccelerationTarget | INT | Acceleration for target move |

DecelerationTarget | INT | Deceleration for target move |

PositionActual | DINT | Actual position of the motor |

TargetActual | DINT | 1ms target position of the motor |

PositionError | DINT | Error between actual and target |

SpeedActual | DINT | Actual speed of the motor |

CurrentActual | INT | Actual current percentage of the motor (0.1% rated) |

OverloadActual | INT | 0.1% of overload torque |

DCVoltage | INT | 24V DC input value at 0.1V |

AnalogIN | INT | 10bit analog input (0-1023) |

DigitalIN | SINT | Read digital inputs |

DigitalOUT | SINT | Set digital outputs |

Temperature | SINT | Drive temperature in °C |

ErrorCode | SINT | ErrorCode is currently reserved and returns 0. |

ReadAddress1 | INT | Address of register to read |

ReadValue1 | DINT | Value of read register |

ReadValueAddress1 | INT | Address of the current read register |

WriteValue1 | DINT | Register write value |

WriteRegister1 | INT | Write register address |

CM1T_Controlword

Name | Data Type | Description |

|---|---|---|

Start | BOOL | Start/New set point |

Halt | BOOL | Halt current motion |

Relative_Move | BOOL | Execute position move as relative |

Speed_Control | BOOL | Execute move as a speed only move |

Disable | BOOL | Disable the drive |

Reset_Error | BOOL | Reset error with rising edge |

Set_to_Zero | BOOL | Set the current position to zero with rising edge |

Home | BOOL | Home the motor with rising edge |

CM1T_DriveStatus

Name | Data Type | Description |

|---|---|---|

StatusValue | SINT | Motor status and error type |

StatusValue1 | SINT | Additional motor status |

In_Position | BOOL | Motor is in position and ready to move |

Moving | BOOL | Motor is currently moving |

Disabled | BOOL | Drive is disabled |

Error | BOOL | Drive is in error state |

MoveComplete | BOOL | Move is completed |

NewStartRequired | BOOL | Rising edge required to restart motion |

HomeAchieved | BOOL | Homing has been achieved |

CML Operation

CM1T_CMLAxis

The CM1-T_CMLAxis data type defines how the bytes are assigned withing the IO message.

Name | Data Type | Description |

|---|---|---|

Input | SINT[60] | Data coming from the CM1-T |

Output | SINT[44] | Data going to the CM1-T |

us50Counter | DINT | Motor 50us counter |

DriveStatus | CM1T_DriveStatus | Drive status |

PositionActual | DINT | Actual position of the motor |

TargetActual | DINT | 1ms target position of the motor |

PositionError | DINT | Error between actual and target |

SpeedActual | DINT | Actual speed of the motor |

CurrentActual | INT | Actual current percentage of the motor (0.1% rated) |

OverloadActual | INT | 0.1% of overload torque |

DCVoltage | INT | 24V DC input value at 0.1V |

AnalogIN | INT | 10bit analog input (0-1023) |

DigitalIN | SINT | Read digital inputs |

DigitalOUT | SINT | Set digital outputs |

Temperature | SINT | Drive temperature in °C |

ErrorCode | SINT | (1) - ErrorCode is currently unused and returns 0. Use MotorStatus to get motor error information |

WriteValue | DINT[5] | Register write value (array) Address of register to read |

ReadValue | DINT[5] | Value of read register (array) |

WriteAddress | INT[5] | Write register address (array) |

ReadAddress | INT[5] | Read address register (array) |

ReadValueAddress | INT[5] | Address of the current returned read register (array) |

CM1T_CMLDriveStatus

Name | Data Type | Description |

|---|---|---|

StatusValue | SINT | Motor status and error type |

StatusValue1 | SINT | Additional motor status |

In_Position | BOOL | Motor is in position and ready to move |

Moving | BOOL | Motor is currently moving |

Disabled | BOOL | Drive is disabled |

Error | BOOL | Drive is in error state |

HomeAchieved | BOOL | Homing has been achieved |

Add-On Instructions

Direct Control Operation

The following tables outlines the available add-on instructions

Name | Description | Required |

|---|---|---|

CM1T_DataExchange | Exchanges data between the drive and the drive variable | Yes |

CM1T_Enable | Enables the motor | No |

CM1T_Disable | Disables the motor | No |

CM1T_ClearFault | Clears any faults on the drive | No |

CM1_TControlMode | Set the type of control mode required | No |

CM1T_MoveAbsolute | Executes an absolute position move | No |

CM1T_MoveRelative | Executes a relative position move | No |

CM1T_MoveSpeed | Executes a speed move | No |

CM1T_MoveTorque | Executes a torque move | No |

CM1T_MoveHome | Executes a home routine | No |

CM1T_ReadRegister | Read a motor register value | No |

CM1T_WriteRegister | Write a value to a motor register | No |

CM1T_DataExchange

This AOI is required if any other AOIs are used. One instance is required for each CM1-T axis being controlled.

It has a number of functions

It exchanges data between the motor connections and the motor/drive tag.

It places the Controlword bits into the Controlword data type

It retrieves the drive status and places it into the DriveStatus variable.

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1T_DataExchange | CM1T_DataExchange | Tag | Instance tag for the AOI |

DriveInput | AB:ETHERNET_MODULE_SINT_32Bytes:I:0 | Tag | Module defined connection input for the CM1-T |

DriveOutput | AB:ETHERNET_MODULE_SINT_20Bytes:O:0 | Tag | Module defined connection output for the CM1-T |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

Execution

Condition | Action |

|---|---|

Prescan |

|

Rung Condition - TRUE |

|

Rung Condition - FALSE | N/A - rung-condition-out is set to false |

CM1T_Enable

This AOI enables the motor and drive. Torque will be present.

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1T_Enable | CM1T_Enable | Tag | Instance tag for the AOI |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

Execution

Condition | Action |

|---|---|

prescan | N/A - rung-condition-out is set to false |

rung-condition-in is true |

|

rung-condition-in is false | N/A - rung-condition-out is set to false |

CM1T_Disable

This AOI disables the motor and drive. Torque will not be present

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1T_Disable | CM1T_Disable | Tag | Instance tag for the AOI |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

Execution

Condition | Action |

|---|---|

prescan | N/A - rung-condition-out is set to false |

rung-condition-in is true |

|

rung-condition-in is false | N/A - rung-condition-out is set to false |

CM1T_ClearFault

This AOI clears any drive fault/error condition. This will also enable the motor. The rung-out-condition indicates the drive error state (true or false).

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1T_ClearFault | CM1T_ClearFault | Tag | Instance tag for the AOI |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

Execution

Condition | Action |

|---|---|

Prescan | N/A |

rung-condition-in is true |

|

rung-condition-in is false |

|

CM1T_ControlMode

This AOI set the motion control mode.

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1T_Disable | CM1T_ControlMode | Tag | Instance tag for the AOI |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

ControlMode_Value | DINT | Immediate/Tag | A value that sets the type of control mode required 0 - POSITION |

Execution

Condition | Action |

|---|---|

prescan | N/A - rung-condition-out is set to false |

rung-condition-in is true |

|

rung-condition-in is false | N/A - rung-condition-out is set to false |

CM1T_MoveAbsolute

This AOI will execute an absolute position move.

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1T_MoveAbsolute | CM1T_MoveAbsolute | Tag | Instance tag for the AOI |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

Position | DINT | Immediate/ | Target absolute position |

Speed | DINT | Immediate/ | Target speed |

Acceleration | INT | Immediate/ | Target acceleration |

Deceleration (optional) | INT | Immediate/ | Target deceleration |

Execution

Condition | Action |

|---|---|

prescan | N/A - rung-condition-out is set to false |

rung-condition-in is true |

|

rung-condition-in is false | N/A - rung-condition-out is set to false |

CM1T_MoveRelative

This AOI will execute a relative position move.

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1T_MoveRelative | CM1T_MoveRelative | Tag | Instance tag for the AOI |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

Position | DINT | Immediate/ | Target absolute position |

Speed | DINT | Immediate/ | Target speed |

Acceleration | INT | Immediate/ | Target acceleration |

Deceleration (optional) | INT | Immediate/ | Target deceleration |

Start | BOOL | Immediate/ | 0 → 1 transition will execute a new relative move. If a motion is currently in process it will increment relative to the current position |

Execution

Condition | Action |

|---|---|

prescan | N/A - rung-condition-out is set to false |

rung-condition-in is true |

|

rung-condition-in is false | N/A - rung-condition-out is set to false |

CM1T_MoveSpeed

This AOI will execute a speed move.

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1T_MoveSpeed | CM1T_MoveSpeed | Tag | Instance tag for the AOI |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

Speed | DINT | Immediate/ | Target speed |

Acceleration | INT | Immediate/ | Target acceleration |

Deceleration (optional) | INT | Immediate/ | Target deceleration |

Execution

Condition | Action |

|---|---|

prescan | N/A - rung-condition-out is set to false |

rung-condition-in is true |

|

rung-condition-in is false | N/A - rung-condition-out is set to false |

CM1T_MoveTorque

This AOI will execute a torque move.

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1T_MoveSpeed | CM1T_MoveSpeed | Tag | Instance tag for the AOI |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

Torque | INT | Immediate/ | Target torque |

MaxSpeed | DINT | Immediate/ | Target speed |

Execution

Condition | Action |

|---|---|

prescan | N/A - rung-condition-out is set to false |

rung-condition-in is true |

|

rung-condition-in is false | N/A - rung-condition-out is set to false |

CM1T_ReadRegister

This AOI loads a register address to read. It returns the register value. The value is returned when the ReadRegister (output) address and the ReadValueAddress (input) address are equal.

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1T_ReadRegister | CM1T_ReadRegister | Tag | Instance tag for the AOI |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

Address | INT | Immediate/ | Address of register to read |

Value | DINT | Tag | Tag to load the returned value |

Done | BOOL | Tag | Optional output indicating the value has been returned. |

Execution

Condition | Action |

|---|---|

prescan | N/A - rung-condition-out is set to false |

rung-condition-in is true |

|

rung-condition-in is false | N/A - rung-condition-out is set to false |

CM1T_WriteRegister

This AOI loads a register address and value to write. Once the write cycle is complete the done output is set.

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1TWriteRegister | CM1T_WriteRegister | Tag | Instance tag for the AOI |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

Address | INT | Immediate/ | Address of register to write |

Value | DINT | Immediate/ | Tag/value to load into the write value |

Done | BOOL | Tag | Optional output indicating the value has been written. |

Execution

Condition | Action |

|---|---|

prescan | N/A - rung-condition-out is set to false |

rung-condition-in is true |

|

rung-condition-in is false | N/A - rung-condition-out is set to false |

CML Operation

The following tables outlines the available add-on instructions

Name | Description | Required |

|---|---|---|

CM1T_CMLDataExchange | Exchanges data between the drive and the drive variable | Yes |

CM1T_CMLReadRegister | Reads a motor register | No |

CM1T_CMLWriteRegister | Writes to a motor register | No |

CM1T_CMLDataExchange

This AOI is required if any other CML AOIs are used. One instance is required for each CM1-T axis being controlled.

It has a number of functions

It exchanges data between the motor connections and the motor/drive tag.

It retrieves the drive status and places it into the DriveStatus variable.

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1T_DataExchange | CM1T_DataExchange | Tag | Instance tag for the AOI |

DriveInput | AB:ETHERNET_MODULE_SINT_32Bytes:I:0 | Tag | Module defined connection input for the CM1-T |

DriveOutput | AB:ETHERNET_MODULE_SINT_20Bytes:O:0 | Tag | Module defined connection output for the CM1-T |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

Execution

Condition | Action |

|---|---|

Prescan | N/A - rung-condition-out is set to false |

Rung Condition - TRUE |

|

Rung Condition - FALSE | N/A - rung-condition-out is set to false |

CM1T_CMLReadRegister

This AOI loads a register address to read. It returns the register value. The value is returned when the ReadRegister (output) address and the ReadValueAddress (input) address are equal.

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1T_ReadRegister | CM1T_ReadRegister | Tag | Instance tag for the AOI |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

Slot | SINT | Immediate/ | There are 5 slots available. Enter 1-5. |

Address | INT | Immediate/ | Address of register to read |

Value | DINT | Tag | Tag to load the returned value |

Done | BOOL | Tag | Optional output indicating the value has been returned. |

Execution

Condition | Action |

|---|---|

prescan | N/A - rung-condition-out is set to false |

rung-condition-in is true |

|

rung-condition-in is false | N/A - rung-condition-out is set to false |

CM1T_CMLWriteRegister

This AOI loads a register address and value to write. Once the write cycle is complete the done output is set.

Parameters

Operand | Type | Format | Description |

|---|---|---|---|

CM1TWriteRegister | CM1T_WriteRegister | Tag | Instance tag for the AOI |

CM1T_Axis | CM1T_Axis | Tag | Working tag for the CM1-T axis |

Slot | SINT | Immediate/ | There are 5 slots available. Enter 1-5. |

Address | INT | Immediate/ | Address of register to write |

Value | DINT | Immediate/ | Tag/value to load into the write value |

Done | BOOL | Tag | Optional output indicating the value has been written. |

Execution

Condition | Action |

|---|---|

prescan | N/A - rung-condition-out is set to false |

rung-condition-in is true |

|

rung-condition-in is false | N/A - rung-condition-out is set to false |

Adding CM1-T and AOIs to Project

Download and extract the EtherNet/IP support file.

The file includes the following

Direct Control Operation

CM1T_SampleApplication.ACD - This a sample application built RSLogix. It shows how to

Run the motors in each of the modes

Reset from faults

Enable/Disable the motor

User Data Types (UDT)

Add-On Instructions (AOI)

CML Operation

CM1T_CMLSampleApplication.ACD - RSLogix application to read/write motor registers

CM1T_CMLSampleApplication.crp - Control Room project with CML sample program.

Executes incremental move if variable is set (Run, distance, speed and acceleration set from PLC)

Increments counter variable (Variable read in PLC)

User Data Types (UDT)

Add-On Instructions (AOI)

Direct Control Operation

Import User Data Types (UDTs)

The following steps show how to import the UDTs used by the CM1-T module.

Right click on Data Types → User-Defined and select "Import Data Type..."

Browse to the location where the CM1T_AOI support file was extracted. Select the CM1T_Axis and click import.

On the Import Configuration window click OK

The CM1T_Axis, CM1T_Controlword and CM1T_DriveStatus should all have been import as shown below. If they were not repeat steps 1-3 with the CM1T_Controlword and CM1T_DriveStatus.

Import Add-On Instructions (AOIs)

The following steps show how to import the CM1-T modules AOIs. The only required AOI is CM1T_DataExchange. All the other AOIs depend on this one to populate the data type.

Right click on Add-On Instructions and select "Import Add-On Instruction..."

Browse to the extracted AOI folder and select CM1T_DataExchange. Click Import

On the Configuration Import window click OK.

Repeat steps 1-3 until all required AOIs are imported

The Add-On Instruction tree will look as follows once all AOIs are imported

Add CM1-T Module

The following steps show how to add an CM1-T module in RSLogix. At present the EtheNet/IP is in testing and the CM1-T is added a a generic module.

Open an existing project or start a new one

In the Controller Organizer expand I/O Configuration and right click on "Ethernet". Select "New Module"

Search "Generic", Select "ETHERNET-MODULE" and click Create

Fill in the following properties shown below

Name: Give the drive a name. E.g. CM1T_Drive, Axis1, LabelXAxis, etc

Comm Format: Data - SINT

IP Address: Enter the IP Address of the CM1-T you are adding.

Connection Parameters

Input: Assembly Instance = 100, Size = 36

Output: Assembly Instance = 112, Size = 28

Configuration: Assembly Instance = 1, Size = 0

Click OK

The Module Properties window should open. If it does not double click on the newly created module inside the Ethernet heading.

Select the Connection TabSet the packet interval as required. Typically this would be 10ms.

Check the boxes as shown in the picture above

The final set of steps below shows how to add the CM1T_DataExchange AOI and configure it to exchange data between the tag created for the CM1-T and the CM1-T module. A single instance of the CM1T_DataExchange should be created per module. There should never be more than one per module.

Add the CM1T_DataExchange AOI to a rung

Create a CM1T_DataExchange Tag and attached it to this instance. In this example it is called FB_CM1T_DataExchnage

Expand the DriveInput drop down menu and select the CM1T_Drive module input create earlier

Expand the DriveOuput drop down menu and select the CM1T_Drive module output create earlier

Create a new CM1T_Axis tag and attach it to the instruction. This is the tag that will be used in all other AOIs

All CM1-T AOIs are now ready to be used. See the example application for more details on running the motor.

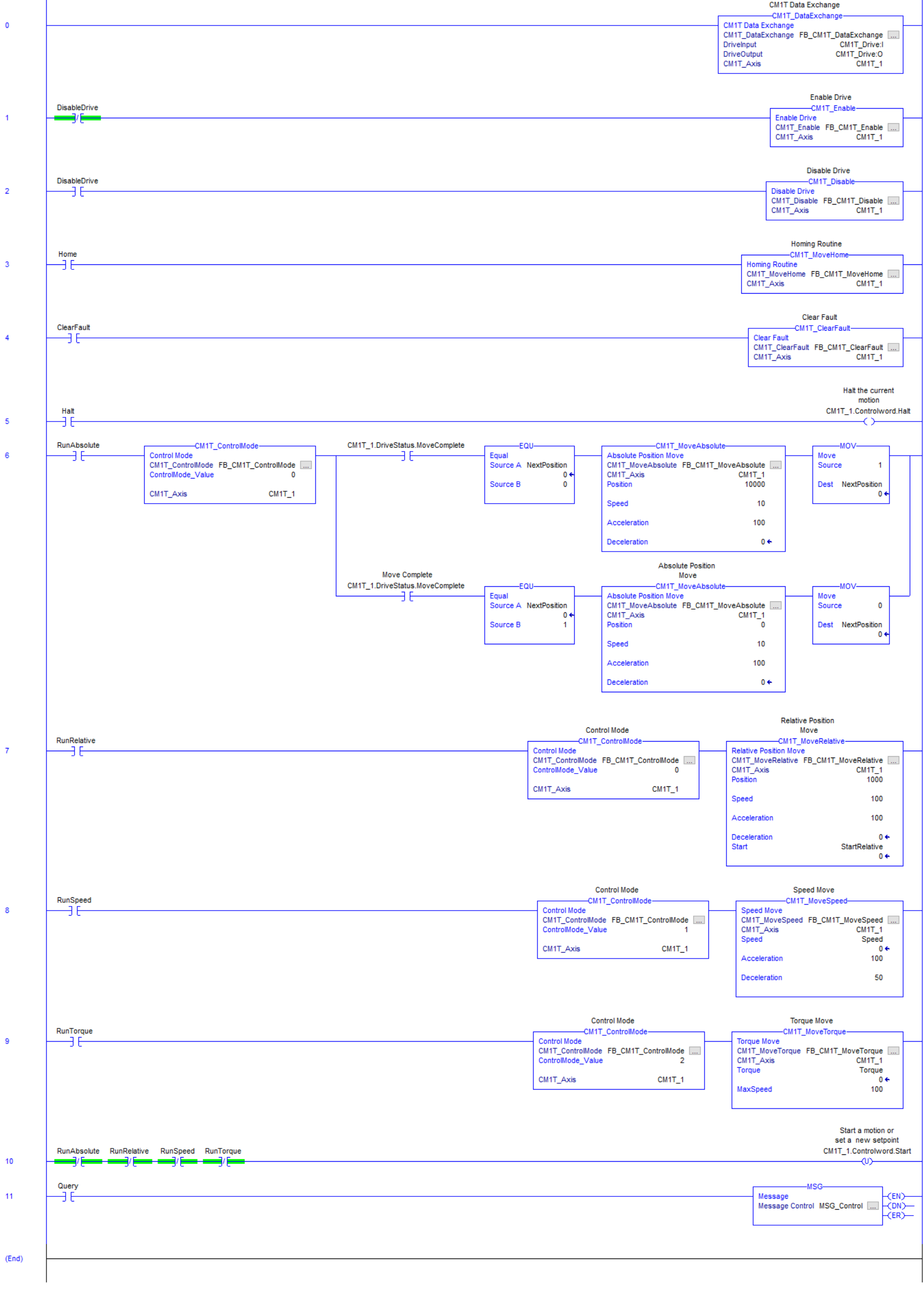

Example Logic - Direct Control Operation Sample

The following logic is from the Direct operation sample application. The example shows how to run the motor in each of the modes, enable, disable, halt, and recover from an error.

CML Operation

Import User Data Types (UDTs)

Following the instructions for Direct Control Operation except import

CM1T_CMLAxis

CM1T_CMLDriveStatus

Import Add-On Instructions (AOIs)

Follow the instructions for Direct Control Operation except import

CM1T_CMLDataExchange

CM1T_CMLReadRegister

CM1T_CMLWriteRegister

Add CM1-T Module

Follow the instructions for Direct Control Operation except on step 4 enter the following configuration data

Name: Give the drive a name. E.g. CM1T_Drive, Axis1, LabelXAxis, etc

Comm Format: Data - SINT

IP Address: Enter the IP Address of the CM1-T you are adding.

Connection Parameters

Input: Assembly Instance = 101, Size = 60

Output: Assembly Instance = 113, Size = 44

Configuration: Assembly Instance = 1, Size = 0

Click OK

Example Logic - CML Operation Sample

The following sample logic is supplied with the AOIs. It requires the motor to be programmed with a CML program. The program does the following

Motor indexes continuously by the distance amount defined by PLC

Motor indexes with speed and acceleration defined by PLC

Indexing is started and stopped by PLC

A counter showing number of indexes is read by the PLC

Appendix

A - Support Files

B - Complete Register Address Map

K Registers

Register | Address | |

|---|---|---|

Hex | Decimal | |

K21 | 16#0115 | 277 |

K22 | 16#0116 | 278 |

K23 | 16#0117 | 279 |

K24 | 16#0118 | 280 |

K25 | 16#0119 | 281 |

K26 | 16#011A | 282 |

K27 | 16#011B | 283 |

K28 | 16#011C | 284 |

K29 | 16#011D | 285 |

K30 | 16#011E | 286 |

K31 | 16#011F | 287 |

K32 | 16#0120 | 288 |

K33 | 16#0121 | 289 |

K34 | 16#0122 | 290 |

K35 | 16#0123 | 291 |

K36 | 16#0124 | 292 |

K37 | 16#0125 | 293 |

K38 | 16#0126 | 294 |

K39 | 16#0127 | 295 |

K40 | 16#0128 | 296 |

K41 | 16#0129 | 297 |

K42 | 16#012A | 298 |

K43 | 16#012B | 299 |

K44 | 16#012C | 300 |

K45 | 16#012D | 301 |

K46 | 16#012E | 302 |

Register | Address | |

|---|---|---|

Hex | Decimal | |

K47 | 16#012F | 303 |

K48 | 16#0130 | 304 |

K49 | 16#0131 | 305 |

K50 | 16#0132 | 306 |

K51 | 16#0133 | 307 |

K52 | 16#0134 | 308 |

K53 | 16#0135 | 309 |

K54 | 16#0136 | 310 |

K55 | 16#0137 | 311 |

K56 | 16#0138 | 312 |

K57 | 16#0139 | 313 |

K58 | 16#013A | 314 |

K59 | 16#013B | 315 |

K60 | 16#013C | 316 |

K61 | 16#013D | 317 |

K62 | 16#013E | 318 |

K63 | 16#013F | 319 |

K64 | 16#0140 | 320 |

K65 | 16#0141 | 321 |

K66 | 16#0142 | 322 |

K67 | 16#0143 | 323 |

K68 | 16#0144 | 324 |

K69 | 16#0145 | 325 |

K70 | 16#0146 | 326 |

K71 | 16#0147 | 327 |

K72 | 16#0148 | 328 |

Register | Address | |

|---|---|---|

Hex | Decimal | |

K73 | 16#0149 | 329 |

K74 | 16#014A | 330 |

K75 | 16#014B | 331 |

K76 | 16#014C | 332 |

K77 | 16#014D | 333 |

K78 | 16#014E | 334 |

K79 | 16#014F | 335 |

K80 | 16#0150 | 336 |

K81 | 16#0151 | 337 |

K82 | 16#0152 | 338 |

K83 | 16#0153 | 339 |

K84 | 16#0154 | 340 |

K85 | 16#0155 | 341 |

K86 | 16#0156 | 342 |

K87 | 16#0157 | 343 |

K88 | 16#0158 | 344 |

K89 | 16#0159 | 345 |

K90 | 16#015A | 346 |

H Registers

Register | Address | |

|---|---|---|

Hex | Decimal | |

H0 | 16#0200 | 512 |

H1 | 16#0201 | 513 |

H2 | 16#0202 | 514 |

H3 | 16#0203 | 515 |

H4 | 16#0204 | 516 |

H5 | 16#0205 | 517 |

H6 | 16#0206 | 518 |

H7 | 16#0207 | 519 |

P Registers

Register | Address | |

|---|---|---|

Hex | Decimal | |

P0 | 16#0300 | 768 |

P1 | 16#0301 | 769 |

P2 | 16#0302 | 770 |

P3 | 16#0303 | 771 |

P4 | 16#0304 | 772 |

P5 | 16#0305 | 773 |

P6 | 16#0306 | 774 |

P7 | 16#0307 | 775 |

P8 | 16#0308 | 776 |

P9 | 16#0309 | 777 |

P10 | 16#030A | 778 |

P11 | 16#030B | 779 |

P12 | 16#030C | 780 |

P13 | 16#030D | 781 |

P14 | 16#030E | 782 |

P15 | 16#030F | 783 |

P16 | 16#0310 | 784 |

P17 | 16#0311 | 785 |

P18 | 16#0312 | 786 |

P19 | 16#0313 | 787 |

P20 | 16#0314 | 788 |

P21 | 16#0315 | 789 |

P22 | 16#0316 | 790 |

P23 | 16#0317 | 791 |

P24 | 16#0318 | 792 |

P25 | 16#0319 | 793 |

S Registers

Register | Address | |

|---|---|---|

Hex | Decimal | |

S0 | 16#0400 | 1024 |

S1 | 16#0401 | 1025 |

S2 | 16#0402 | 1026 |

S3 | 16#0403 | 1027 |

S4 | 16#0404 | 1028 |

S5 | 16#0405 | 1029 |

S6 | 16#0406 | 1030 |

S7 | 16#0407 | 1031 |

S8 | 16#0408 | 1032 |

S9 | 16#0409 | 1033 |

S10 | 16#040A | 1034 |

S11 | 16#040B | 1035 |

S12 | 16#040C | 1036 |

S13 | 16#040D | 1037 |

S14 | 16#040E | 1038 |

S15 | 16#040F | 1039 |

A Registers

Register | Address | |

|---|---|---|

Hex | Decimal | |

A0 | 16#0500 | 1280 |

A1 | 16#0501 | 1281 |

A2 | 16#0502 | 1282 |

A3 | 16#0503 | 1283 |

A4 | 16#0504 | 1284 |

A5 | 16#0505 | 1285 |

A6 | 16#0506 | 1286 |

A7 | 16#0507 | 1287 |

A8 | 16#0508 | 1288 |

T Registers

Register | Address | |

|---|---|---|

Hex | Decimal | |

T1 | 16#0601 | 1537 |

T2 | 16#0602 | 1538 |

T3 | 16#0603 | 1539 |

T4 | 16#0604 | 1540 |

T5 | 16#0605 | 1541 |

T6 | 16#0606 | 1542 |

T7 | 16#0607 | 1543 |

T8 | 16#0608 | 1544 |

M Registers

Register | Address | |

|---|---|---|

Hex | Decimal | |

M0 | 16#0700 | 1792 |

M1 | 16#0701 | 1793 |

M2 | 16#0702 | 1794 |

M3 | 16#0703 | 1795 |

M4 | 16#0704 | 1796 |

M5 | 16#0705 | 1797 |

M6 | 16#0706 | 1798 |

M7 | 16#0707 | 1799 |

R Registers

Register | Address | |

|---|---|---|

Hex | Decimal | |

R0 | 16#0800 | 2048 |

R1 | 16#0801 | 2049 |

R2 | 16#0802 | 2050 |

R3 | 16#0803 | 2051 |

R4 | 16#0804 | 2052 |

R5 | 16#0805 | 2053 |

R6 | 16#0806 | 2054 |

R7 | 16#0807 | 2055 |

R8 | 16#0808 | 2056 |

R9 | 16#0809 | 2057 |

R10 | 16#080A | 2058 |

R11 | 16#080B | 2059 |

R12 | 16#080C | 2060 |

R13 | 16#080D | 2061 |

R14 | 16#080E | 2062 |

R15 | 16#080F | 2063 |

R16 | 16#0810 | 2064 |

R17 | 16#0811 | 2065 |

R18 | 16#0812 | 2066 |

R19 | 16#0813 | 2067 |

R20 | 16#0814 | 2068 |

R21 | 16#0815 | 2069 |

R22 | 16#0816 | 2070 |

R23 | 16#0817 | 2071 |

R24 | 16#0818 | 2072 |

R25 | 16#0819 | 2073 |

N Registers

Register | Address | |

|---|---|---|

Hex | Decimal | |

N0 | 16#0900 | 2304 |

N1 | 16#0901 | 2305 |

N2 | 16#0902 | 2306 |

N3 | 16#0903 | 2307 |

N4 | 16#0904 | 2308 |

N5 | 16#0905 | 2309 |

N6 | 16#0906 | 2310 |

N7 | 16#0907 | 2311 |

N8 | 16#0908 | 2312 |

N9 | 16#0909 | 2313 |

N10 | 16#090A | 2314 |

N11 | 16#090B | 2315 |

N12 | 16#090C | 2316 |

N13 | 16#090D | 2317 |

N14 | 16#090E | 2318 |

N15 | 16#090F | 2319 |

N16 | 16#0910 | 2320 |

N17 | 16#0911 | 2321 |

N18 | 16#0912 | 2322 |

N19 | 16#0913 | 2323 |

N20 | 16#0914 | 2324 |

N21 | 16#0915 | 2325 |

N22 | 16#0916 | 2326 |

N23 | 16#0917 | 2327 |

N24 | 16#0918 | 2328 |

N25 | 16#0919 | 2329 |

V Registers

Register | Address | |

|---|---|---|

Hex | Decimal | |

V0 | 16#0A00 | 2560 |

V1 | 16#0A01 | 2561 |

V2 | 16#0A02 | 2562 |

V3 | 16#0A03 | 2563 |

V4 | 16#0A04 | 2564 |

V5 | 16#0A05 | 2565 |

V6 | 16#0A06 | 2566 |

V7 | 16#0A07 | 2567 |

V8 | 16#0A08 | 2568 |

V9 | 16#0A09 | 2569 |

V10 | 16#0A0A | 2570 |

V11 | 16#0A0B | 2571 |

V12 | 16#0A0C | 2572 |

V13 | 16#0A0D | 2573 |

V14 | 16#0A0E | 2574 |

V15 | 16#0A0F | 2575 |